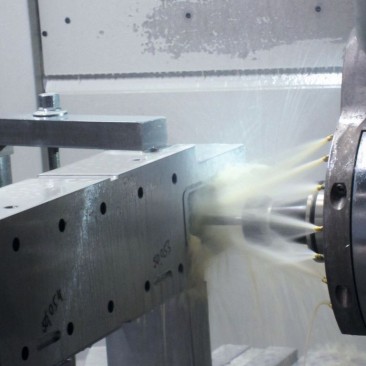

Top class metalworking

Due to order-related production, we are very familiar with constantly changing tasks, so that you do not receive standard products in stock, but the solution tailored to your task. In order to meet the most diverse requirements of each customer and his high demands on precision, quality and flexibility, our modern machinery is universally equipped. This enables us to implement simple but effective solutions according to individual specifications. We offer individual or special production as well as small series in all areas of metalworking. The quality of an industrially manufactured product is largely dependent on the quality of the individual parts, assembly and quality assurance. All three factors are essentially determined by high-precision tools, fixtures and gauges. The provision of these resources presupposes the existence of an efficient resource construction. On the basis of precision engineering, gauge and fixture construction is accustomed to developing and manufacturing precision components. Equipped with a modern machine park, we guarantee a proper and professional order processing even with difficult tasks.

Due to order-related production, we are very familiar with constantly changing tasks, so that you do not receive standard products in stock, but the solution tailored to your task. In order to meet the most diverse requirements of each customer and his high demands on precision, quality and flexibility, our modern machinery is universally equipped. This enables us to implement simple but effective solutions according to individual specifications. We offer individual or special production as well as small series in all areas of metalworking. The quality of an industrially manufactured product is largely dependent on the quality of the individual parts, assembly and quality assurance. All three factors are essentially determined by high-precision tools, fixtures and gauges. The provision of these resources presupposes the existence of an efficient resource construction. On the basis of precision engineering, gauge and fixture construction is accustomed to developing and manufacturing precision components. Equipped with a modern machine park, we guarantee a proper and professional order processing even with difficult tasks.

Our machinery

- 25 turning and milling centres

- Drilling and jig boring machines

- honing machines

- cylindrical grinding machines

- jig grinders

- surface grinding machines

- Shape grinding machines

- sawing machines

- Air-conditioned measuring rooms

- Welding (WIG, MAG)

- CAM interface on all machines

Our range of service

- Milling up to 5000x2000x1100 mm

- Turning up to ø2000 mm

- Grinding, honing, polishing

- Machining of special materials

- Assembly of assemblies and modules

- Accuracies up to 0.001 mm

- 5-axis simultaneous machining

- Sawing, cutting and burning

- Welding of stainless steels and non-ferrous metals

- heat treatment

- surface refinement

- rough-blasting and UHV cleaning

- Control and switch cabinet construction

- Weight up to 3000 kg

- Measuring up to 2400x1600x1400 mm

- CAM: HyperCAD & HyperMILL